New Construction Building Case

- Commissioning for realizing sustainable building that can last over 100 years - Targeting 40% reduction in annual source energy use at whole facility level and 60% reduction in annual plant energy use -

- The first government building project using Initial Commissioning; Targeting 40% reduction in annual primary energy use

- Total commissioning of a university building and its systems; carbon reduction of 20% or more

- An Example of Initial Commissioning for a Large Hospital

- Japan's First Initial Commissioning

Cx for the HVAC Systems Retrofit Project at Kyoto Station Building

Commissioning for realizing sustainable building that can last over 100 years - Targeting 40% reduction in annual source energy use at whole facility level and 60% reduction in annual plant energy use -

Period

April 2010 - March 2011, April 2014 - June 2017

- 2010 Investigation phase

- 2011 Design development phase

- 2014 Final design phase

- Jan 2015–Jun 2016 Construction Phase

- 2016–2017 Functional tests and Adjustments

- 2017–2019 Optimization

Team

Client: Kyoto Station Building Development Co. , Ltd.(Operation management: JR West Japan General Building Service Co. , Ltd)

Cx Management Team (CMT): Building Services Commissioning Association, (BSCA) Harunori Yoshida(CA, CxPE), Ryuji Yanagihara(CxPE), Yasunori Akashi, Yoshiyuki Shimoda, Shuji Sugiura, Atsuro Oka(CxPE),Hiromasa Aoyama(CxPE), Yuji Yamamoto(CxTE), Katsuaki Yabe,Akira Nakamori, Masaharu Nakamura, Naomiki Matsushita(CxTE)

Engineering Design: NIKKEN SEKKEI LTD, NIKKEN SEKKEI RESEARCH INSTITUTE Naoki Takahashi (CxPE)

Construction Contractors: Takasago Thermal Engineering Co. , Ltd. & Techsia Co., Ltd. JV Tetsuro Inoue (CxTE), Junji Yamaguchi (CxTE) , NESCO

Facility Data

Kyoto Station Building is a multi-use complex opened in 1997 and comprises a hub train station, department store, hotel, theater, and mall. The construction was a part of projects commemorating the 1200th anniversary of the capital’s foundation in Kyoto. The current facility is the fourth generation of the Kyoto station. The building has 16 floors above grade and 3 floors below grade and the gross floor area is 235,942 m2. The size is 60 meters high and 470 meters from east to west. This retrofit project includes major mechanical and pluming updates for this 15 year-old facility.

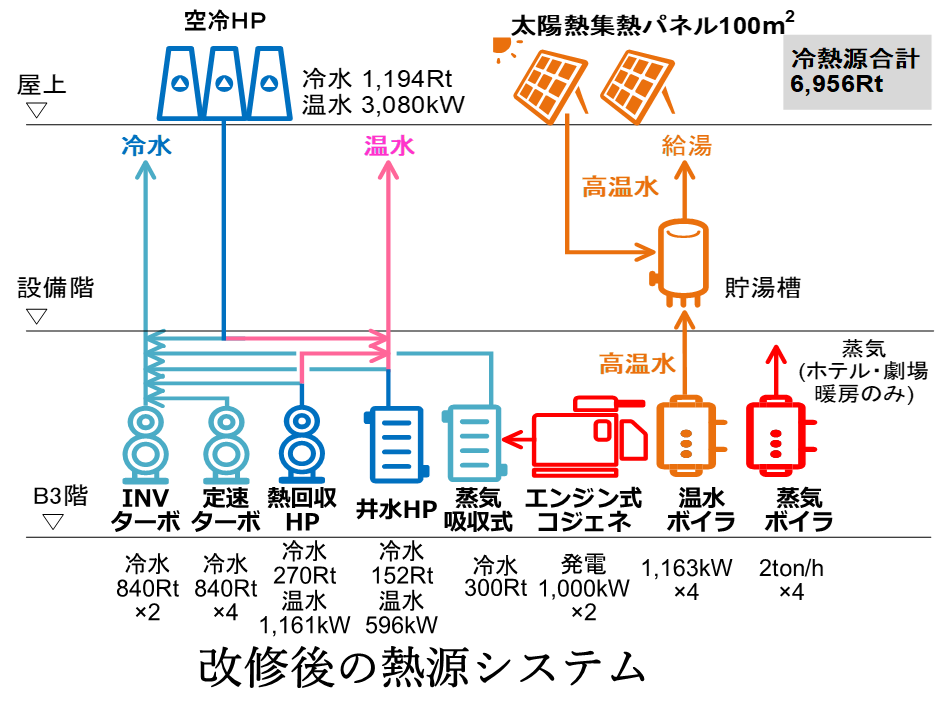

Summary of the Systems Commissioned

Based on the analysis of existing systems and the design phase commissioning, the retrofit plan was finalized. The plan includes following items: 1) Introduce new high efficiency centrifugal chillers and an air-cooling heat pump chiller, 2) Convert the secondary heating system from steam to hot water to avoid excessive heat loss, 3) Introduce geothermal heat pump and solar powered domestic water heating system to incorporate renewable energy, 4) Utilize gas turbine CHP system for Demand Response and the waste heat for chilled water generation using absorption chillers, 5) Optimize outside air flow, and 6) Install VFDs to motors. The project is now in the construction phase.

Summary of Commissioning

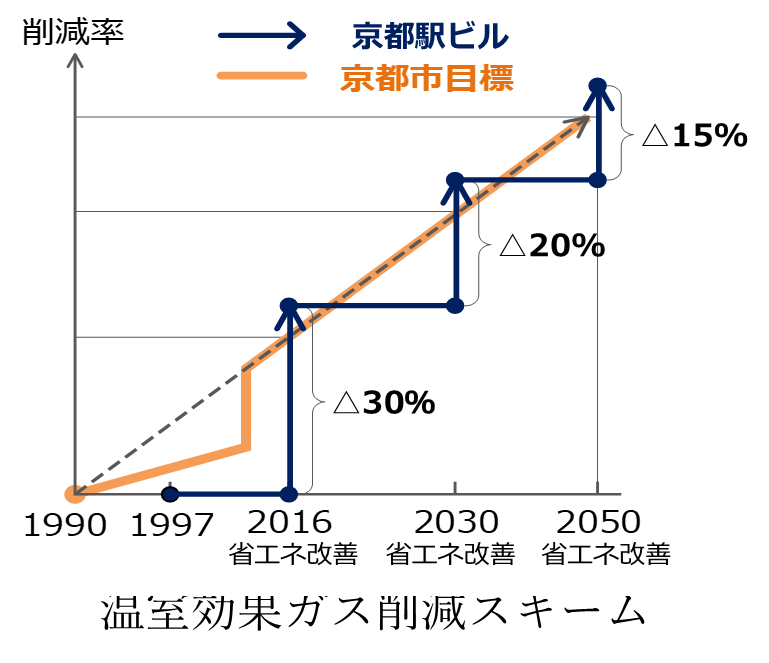

The client set the main objective as a substantial energy use and carbon emission reductions to respond to the City of Kyoto’s environmental initiative. To achieve this objective, the client chose to go through a long-term commissioning from the investigation and analysis of the existing system to the design and construction of the new system.

In the investigation phase, the performance of the existing system was analyzed and problems to be solved were identified. In the design development phase, the Owner's Project Requirements (OPR) were developed. the Cx Team conducted HVAC systems simulation and used the results for the design review. The simulation revealed that the HVAC systems energy use and carbon emission can be reduced by about 60%.

In the final design phase, the target values of the energy use and carbon emission reduction was added to the OPR and details of the system requirements were documented to finalize the OPR. The designer developed the design intent reflecting the OPR.

In the construction delivery contract, functional testing method and quantified pass/fail criteria were clearly documented as the detailed technical specifications for Cx in order to define the Cx tasks performed by the contractor. Then the Cx tasks were paid separately from other part of the construction based on the fulfillment of the tasks defined in the specifications.

In the ongoing construction phase, construction drawings, design changes, and VE plans are reviewed during the Cx meeting. Review meetings focusing on BEMS and control systems are scheduled additionally because these systems play important roles in Cx.

This project was recognized as 2014 low carbon leading project by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT).

New Construction Building Cx for Nagasaki Prefectural Government Building

The first government building project using Initial Commissioning; Targeting 40% reduction in annual primary energy use

Period

July 2012 – March 2014

Team

【Client】 Prefectural Government Building Construction Division,General Affairs Department,Nagasaki Prefectural Goverment

【Cx Management Team(CMT)】 Yasunori Akashi, Daisuke Sumiyoshi, Takao Katsura

【Engineering Design】 NIKKEN SEKKEI LTD,MATSUBAYASHI ARCHITECTURAL DESIGN OFFICE Co., Ltd. & IKEDA ARCHITECTS Co., Ltd. JV Koki Shiratsuchi(CxPE)

Facility Data

The construction of Nagasaki Prefectural Government Building started in 2014 and the planned completion date is in 2017. The target of Cx is the administration building (8 floors, 46,565 m2) and the prefectural assembly building (5 floors, 6,699 m2).

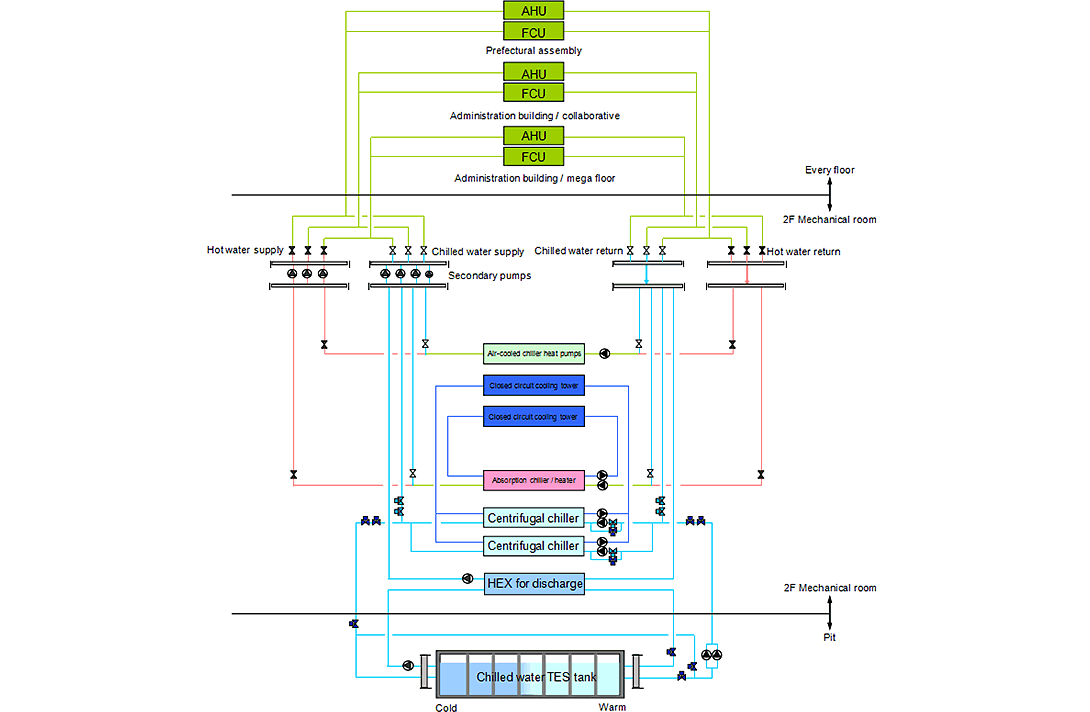

Summary of the Systems Commissioned

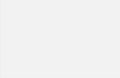

The main target of Cx is HVAC systems including plant and air-handling systems. The heat source plant consists of centrifugal chillers, air-cooled chiller heat pumps, gas fired absorption chiller, and a water thermal energy storage (TES) system. The air-handling system consists of outside air handling units (OAHUs), air handling units (AHUs), and Fan-coil units (FCUs). The latent load will be handled by the OAHUs, whereas the sensible load will be handled by AHUs and FCUs.

Summary of Commissioning

Design phase Cx was conducted to achieve cost and environmental requirements for a government building. The best combination of plant equipment was selected, and the plant capacity was determined based on the peak load calculation using ESUM. A system simulation using LCEM indicates the primary energy use can be reduced by 40% or more compared to typical government buildings. Simulation studies were conducted to analyze the indoor environment and to verify the natural ventilation effects. The specifications for the functional testing during the operation phase were developed to assure the achievement of the required performance.

New Construction Building Cx of Research Institute Building, Nagoya University (Higashiyama Campus)

Total commissioning of a university building and its systems; carbon reduction of 20% or more

Period

May 2011 to March 2014

Team

CMT: Nobuo Nakahara, Masaya Okumiya, and other in-house members; Cx-T: Gen Taniguchi (Campus Planning & Environment Management Office) and others

Okumiya Laboratory, Nagoya University

CRP: Facilities Control Department, Nagoya University, designer, contractor

Facility Data

This facility is a newly built Phase I section of a construction project called the Redevelopment of the Former Nuclear Research Department on the Higashiyama Campus of Nagoya University. The building is 8 stories tall and the total floor area is 7,000 square meters.

Summary of the Systems Commissioned

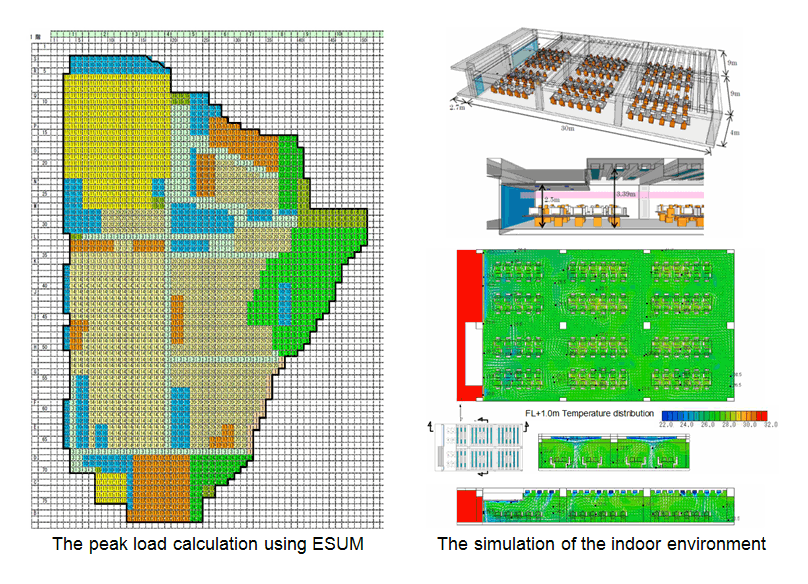

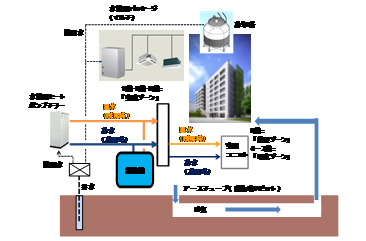

High-performance technologies are used throughout the building including earth tubes and eco shafts. The central plant has heat pump chillers using well water and water thermal storage system. The HVAC secondary system consists of water cooled packages using well water and large temperature difference FCUs. The target energy performance is an annual source energy consumption of 1.86 GJ/m2 per year, lower than the typical energy consumption in a similar use building on the campus by 20% or more.

Summary of Commissioning

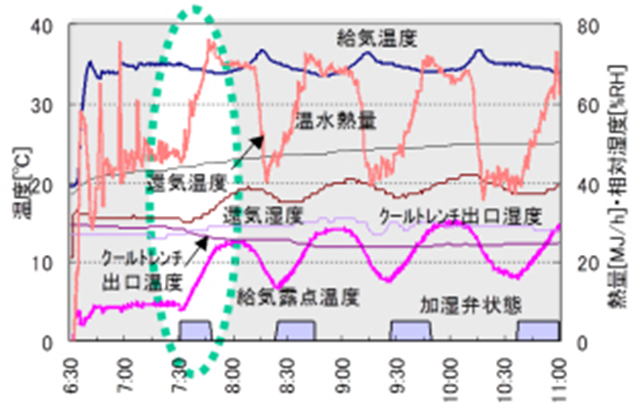

The cooling and heating effects of the earth tubes as an architectural energy-saving device, as well as the temperature rise from eco shafts, were confirmed during the design phase through simulations. For the heat source systems, LCEM and HVACSIM+ were used to evaluate the OPR targets during the basic design and construction documentation phases. During equipment selection in the construction phase, the target and estimated energy consumption, applicable when the building is in actual operation, were determined. The functional performance tests were performed based on the descriptions in the building automation and controls documents. The performance tests evaluated the central plant performance for each operation mode, thermal storage balance, charging and burning profiles, and load shifting ratio. The performance of the controls for the secondary water loop was also tested. Control parameters were adjusted to optimize the operation based on the results of the functional performance tests.

New Construction Building Cx of Japanese Red Cross Medical Center

An Example of Initial Commissioning for a Large Hospital

Period

November 2005 to April 2007

Team

Nobuo Nakahara, Hideki Yuzawa, Toru Kasagi, and Nobuo Miyai

Facility Data

Initial commissioning of a large hospital was conducted during the planning, design, and ordering phases.

Structure: Steel

Scale: 12 floors above ground, 4 floors below ground

Total floor area: 80,906 square meters

Summary of the Systems Commissioned

The design phase commissioning was conducted for a new medical center of the Japanese Red Cross. The name of the project is the Rebuilding Plan of the Hiroo Area of the Japanese Red Cross Medical Center . Optimum energy and central plant systems were studied using simulation and candidate systems were proposed.

Summary of Commissioning

Optimum systems were chosen using the simulation programs TES_ECO and FACES during the planning and design phases of the hospital's central plant system.

The following were examined in the optimization:

- Effects of the use of unused energy

- Heat recovery method

- Effects of the use of air source heat pumps

- Capacity ratio of electric equipment to gas equipment

- Priority order of operation

New Construction Building Cx of (Former) Yamatake Environmental Engineering Center

Japan's First Initial Commissioning

Period

May 2000 to September 2001

Team

Nobuo Nakahara, Hideki Yuzawa, Toru Kasagi, and Hajime Onojima

Facility Data

Japan's first initial commissioning of HVAC systems in a research facility with thermal storage tanks

Structure: Steel

Scale: 4 floors above ground

Building coverage: 702.67 square meters

Total floor area: 695.75 square meters

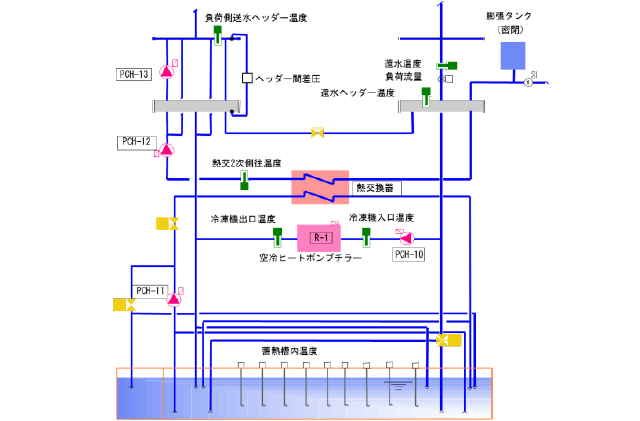

Summary of the Systems Commissioned

Central plant: Air-cooled heat pump chillers and water thermal storage system

Secondary Systems: 1F, Packaged DX units

2F: Task and ambient air conditioning

3F: VAV air-handling system

4F: Radiant heating and cooling with building mass, and natural ventilation system

Summary of Commissioning

As the project was Japan's first initial commissioning project, it made a major contribution to the later development of commissioning practice. The team applied the processes outlined in the commissioning guidelines and prepared the necessary documents. The team proposed and conducted functional performance tests for systems including thermal storage tanks. The commissioning activities improved the operability of the HVAC systems and enabled continuous verifications of the performance.